|

|

| HOME ABOUT US OIL & GAS HEATING & VENTILATING FURNACES & OVENS OTHER APPLICATIONS ONLINE SHOP NEWS CONTACT US LOCATION | |

|

Caledon Controls Ltd

|

What Are Thyristors?

Thyristors are very robust devices in semiconductor terms - more so than transistors or IGBTs and are well suited to service in industrial environments. Each device conducts current in one direction only, and to control an AC load two devices are connected in reverse parallel. The thyristor controllers we supply are assemblies of devices wired for the control of AC loads, together with all the necessary control electronics and protection devices, enclosed in a unit suitable for mounting in a control cabinet. Why Use Thyristors? Thyristors are the preferred method of power control in heating applications, offering silent, long life control. Although it is possible to use electromechanical contactors in many applications with resistive loads, the switching frequency required to obtain good temperature control means that in higher power applications, contact life is rarely longer than a year. By contrast thyristors have no short term wearout mechanism, and will operate reliably for the lifetime of most plant. The products described in this brochure are generally much more robust than solid state relays, offering much better surge withstand capability, and operation at higher ambient temperature. They are also fully engineered with built in snubbers, MOV spike protection where appropriate, semiconductor fuses and generous heatsinks. Most of our controllers are designed for 3-phase loads. They can use 2-leg control (SRC2000, RLS2000 series) in which 2 of the 3 lines of a 3-phase 3-wire load (no neutral) are controlled and the third is connected directly to the load, or 3-leg control (SRC3000, RLS3000, STC3000 series) of a 3-wire or 4-wire load in which all 3 lines are controlled. Firing Modes The thyristor is basically a switch, which can be switched on at any time, but can only be switched off when the current flowing through it is zero, which occurs twice per cycle in AC heating applications. Heating power is controlled by switching the thyristor on and off, and varying the relative proportion of on-time and off-time. There are two fundamental modes of control (firing modes):- Whole cycle, or burst fire control, in which the thyristor is switched on at the start of a supply cycle and switched off again after one or more cycles (or half cycles). Phase angle control (cycle chopping, as used in light dimmers), in which the thyristor is switched on (fired) at some delayed time after the start of every half cycle, and switches off at the end of the half cycle (when the current falls to zero). With zero firing delay the whole half cycle is conducted. As the firing delay is increased less and less of the half cycle is conducted. Application Resistive Loads For pure resistive loads burst fire is normally the preferred method of control because it minimises radio frequency interference and harmonic distortion, and has unity power factor. A typical burst fire cycle time is 1 second on and 1 second off (at 50% of full power). Our SRC range of thyristor stacks operate in this mode. As standard they accept a 'logic' input signal to switch them on and off, and the associated temperature controller provides this logic signal and determines when they switch on and off, and how fast they switch. The SRC range of thyristors are designed to switch on at the next zero voltage crossing of the AC supply after the logic demand signal goes high, and switch off when the current next passes through zero after it goes low. For very fast loads (infra-red heaters), or silicon carbide elements, or loads being supplied by a generator set, the thyristor stack may be driven in single cycle burst fire mode, using our CB17 controller. This is very fast burst fire, in which, for example, 50% output is created by one cycle on followed by one cycle off. More information is provided in the CB17 data sheet. Our RLS2000 and RLS3000 thyristor controllers accept an analogue control signal (0-5V, 4-20mA etc.) and may be configured by DIP switch to operate in burst fire mode or single cycle burst fire mode. The RLS3000 units can also operate in phase angle or soft start burst fire modes (see below) Transformer Coupled Loads Many high temperature furnaces use low voltage graphite or carbon fibre elements or similar, fed via a transformer. Care must be exercised when switching transformers, otherwise the high inrush current associated with random switching, or zero voltage switching will overheat the transformer, blow the semiconductor protection fuses or damage the thyristors. We manufacture three thyristor ranges suitable for this type of load, the STC3000 range, the TLV1000 range and the RLS range. The STC3000 (3-phase) and TLV1000 (single phase) ranges operate in phase angle mode, or soft start burst fire mode (in which the start of each burst is ramped up to full output over several cycles in phase angle mode). Phase angle mode offers very smooth control, but suffers from poor power factor at reduced power outputs, and creates harmonic distortion and radio frequency interference. The RLS2000 range can operate in delayed firing angle burst fire mode or soft start burst fire mode and may be used in applications where previously our now obsolete STA203 series were used. The RLS3000 series can operate in phase angle or soft start burst fire modes (in addition to other modes suitable only for resistive loads). Heaters with Low Cold Resistance Several heater types, including molybdenum and molybdenum disilicide have very low resistance when cold. The thyristor stack must limit the current supplied to the heater until it has warmed up and its resistance increased. With thyristors this can only be done using phase angle control. Our STC3000 range of thyristors has comprehensive current, power and voltage limit functions. More information is available in the product data sheets and manuals. Large Process Heaters Large process heating applications, for example fuel oil heating or fuel gas heating, require very high power inputs. If this power is controlled using one thyristor stack operating in burst fire mode the very high current being switched on and off can give rise to unacceptable voltage flicker on the supply. Similarly, if phase angle control was chosen, unacceptable levels of harmonic distortion would result. The solution is to separate the heater into several stages of smaller power rating and use a load sequencer to control them. Our LSC2 and LSC2A (newest) load sequencers accept an analogue input which is proportional to heating demand, and switch on stages of heating in turn to meet the demand. All but one of the stages is either on or off, and the correct number of these on / off stages is switched on to almost meet the demand. The other stage is a 'modulating' stage, and its output is adjusted to exactly make up the balance of the required heating demand. See the product data sheets for more information. We are always ready to advise. Please do not hesitate to contact us if you require clarification or applications advice. |

| Website Design by DM Web Solutions Ltd | ©Caledon Controls Ltd |

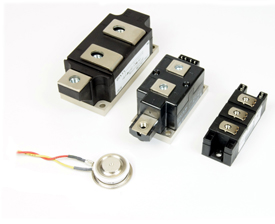

The thyristor, or silicon controlled rectifier (SCR) is a semiconductor device which can be used to switch electric currents. The thyristor was invented in 1957, and today devices are available which are suitable for switching currents ranging from a few milliamps at tens of volts to thousands of amps at thousands of volts.

The thyristor, or silicon controlled rectifier (SCR) is a semiconductor device which can be used to switch electric currents. The thyristor was invented in 1957, and today devices are available which are suitable for switching currents ranging from a few milliamps at tens of volts to thousands of amps at thousands of volts.